Call us now : +919811389091

Back to top

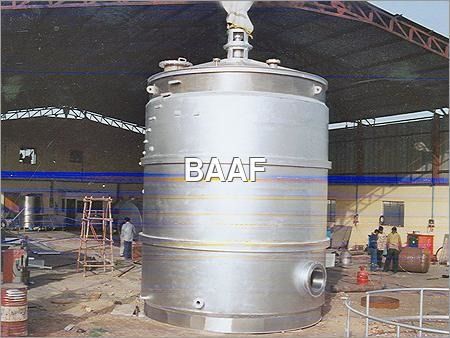

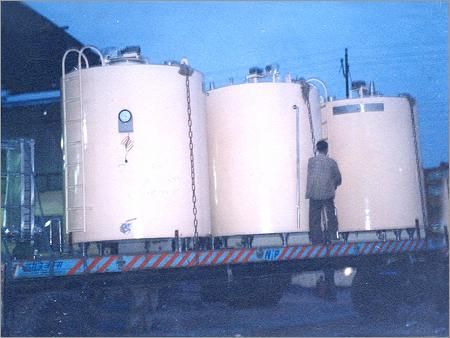

Top-notch quality equipment for dairy, food, chemical, beverages, brewery, Milk powder plants, Cream chillers, butter churns, mineral water, Milk Storage Tank, chemical and paint industries at reasonable price.....

About Us

Have

you ever wondered how the dairy products and processed foods we consume

are made available to us? Well, sophisticated machinery to produce the

same is the answer. Baaf Engineers (P) Ltd. has been

successfully catering to the domestic market with its range of

sophisticated equipment for dairy and food industries, also including

beverage, brewery, chemical and paint industries etc since its

commencement in 1997. We are a leading manufacturer and supplier of equipment like

Milk Reception, Processing and Packaging Equipment, Poly Pack Plants,

Milk Evaporating & Drying Plants, Chemical Plants, Varnish Kettles, Can

Conveying & Washing Machines, Ink Plants, Milk/Cream Chillers and Pasturizers, Inline Filters, Crate Washers, Roller Drier Plants, Can Scrubbers, Ghee Pumps, Pressure Vessels, Cheese Making Equipments, etc. We are also an importer and exporter of Dairy Machinery.

We are engaged in design, engineering, manufacturing, fabrication, site installation and commissioning of these plants on turnkey basis.

It is a matter of privilege for us to be engaged in fabrication of

stainless/mild steel and manufacture machine/custom built equipment for

all types of industries. We have fabricated ropaque storage silos,

varnish kettles, pre-mixers and post blenders for chemical industries.

Product Range

Our

products have application in varied sectors such as dairy, food,

beverages, brewery, mineral water, chemical and paint industries, which

is why we employ superlative quality raw materials like stainless

steel/mild steel and insulation material. We enjoy diversity, not just

in our range of products, but also in terms of their popularity with

our clientele, which is spread in most parts of the country. Our

customer-driven firm is engaged as a renowned manufacturer, exporter,

importer and supplier of the below enumerated equipment:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Our Infrastructure

- Manufacturing unit spread at an area of 4000 sq. meters

- Appropriately located at UPSIDC Surajpur Industrial Area, Greater Noida, Uttar Pradesh with facilities of manufacturing, fabrication, polishing, buffing and sand blasting activities

- Succeeded in fabrication of milk storage tanks from 1000 ltr. to 60,000 ltr. capacity, apart from fabrication, erection and commissioning of dairy pants on turnkey basis from 1000 ltr./day to 250000 ltr./day capacity including milk powder plants from 5 tonnes to 12 tonnes per day capacity

- Technically skilled and trained workforce

- Fully equipped infrastructure for designing, manufacturing, erecting and commissioning of equipment

- Sophisticated heavy duty machinery like lathe machine, radial drill machine, drill machine, hand drill machine, shaft grinding machine, arc welding rectifier, welding generator, plasma cutter, plate rolling machine, sheet press machine, pug machinery, hand gas cutting set, hand cutter, chain pulley block, quality control instruments, generator set.

Quality Quotient

Exclusive

quality control instruments are employed to conduct stage wise quality

checks starting from the initial level of manufacturing process till

the attainment of our final and finished products. These ascertain high

quality and unparalleled equipment with outstanding results at the

advantage of our eminent clients, who deserve only the best.

Our Clientele

Baaf Engineers (P) Ltd. is associated with renowned companies, who form a part of its customer base. They include:

-

Parag Dairy

-

Uttaranchal Dairy Federation

-

Nestle India Ltd.

-

Heinz India Ltd.

-

Asian Paints Ltd.

-

Berger Paints India Ltd.

-

DIC India Ltd.

-

Dairy India (P) Ltd

-

Lakshay Food Pvt. Ltd.

-

Vlsad Distt. Coop. Milk Union Limited (AMUL)

-

UCDF Uttarakhand

-

Gopalji Dairy Foods (P) Ltd

-

M/S Yasoda Milk & Dairy Products

-

Maneesh Milk Products Pvt. Ltd.

-

Aastha Logistics Pvt. Ltd.

-

Mother Dairy

-

Manish Food Industries

-

Bhandara Jila Dugdh Utpadan Sahkari Sangh Maryadit

Send Inquiry

Send Inquiry Send SMS

Send SMS